The manufacturing industry is constantly changing and evolving. Because of this, challenges are bound to happen. Supply chain disruptions have been a particular nuisance in recent months due to the global pandemic. 60% of manufacturing companies are still experiencing supply chain issues in some form.

Sustainability challenges are an ongoing issue as well. The speed that manufacturers are expected to deliver every week puts a lot of pressure on our environment, and more consumers are demanding meaningful changes to their practices. The World Economic Forum reported that the manufacturing industry is responsible for 23% of the carbon emissions in the United States.

Worker shortages are also looming as the pandemic has gone on. There are too many jobs open and not enough people willing to fill them. This is a challenge across all industries as people have started to shift their lifestyles and careers. Manufacturers must find ways to improve the workplace and increase wages to fill the gap from worker shortages.

Meeting the Challenges with Smart Manufacturing

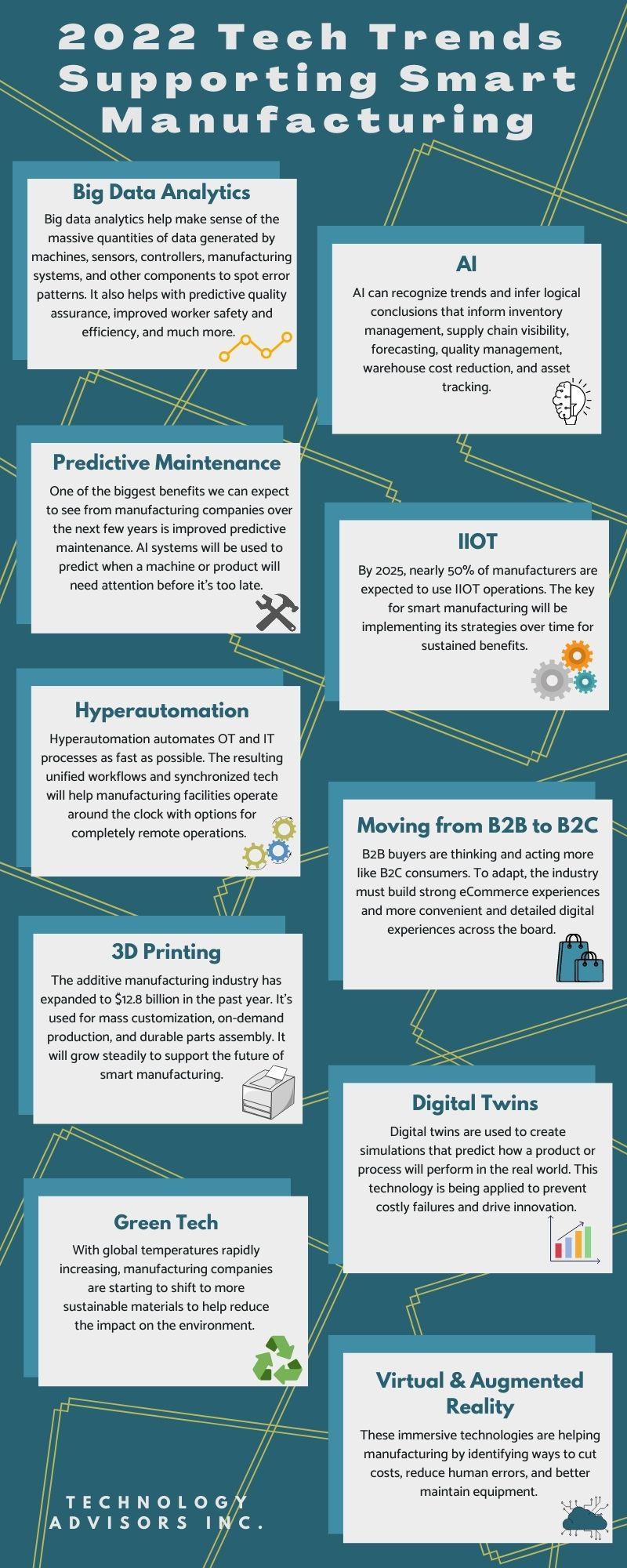

Adopting a full-scale smart manufacturing approach can help manufacturers overcome these challenges by automating processes, reducing waste, and streamlining the supply chain. The industry can use smart manufacturing initiatives to leverage technologies like AI and machine learning for automation and increased efficiency. Recycling, refurbishing, and remanufacturing processes applied to each stage of manufacturing can reduce waste and cut costs, thus diminishing a company’s carbon footprint. Digitalized processes also provide real-time insights to support quick decision-making that keeps manufacturers on top of sustainability goals. With these initiatives in mind, these are the top tech trends supporting smart manufacturing in 2022:

#1 Big Data Analytics

The manufacturing sector compiles data from a range of sources, in multiple formats. Pulling meaningful insights from that information is nearly impossible without the assistance of big data analytics. Big data allows manufacturing companies to improve quality control and transparency within the supply chain. It can be used to spot error patterns, do predictive quality assurance, share insights between different factories or organizations, improve worker safety and efficiency, and streamline product innovation. Big data analysis lends itself to smart manufacturing by making sense of the massive quantities of data that are continuously generated by machines, sensors, controllers, manufacturing systems, and other components involved in manufacturing output.

#2 AI

AI improves many manufacturing operations by going beyond the limitations of traditional data analysis. Because it can recognize trends and infer logical conclusions from massive swaths of data, it has powerful applications in inventory management, supply chain visibility, forecasting, quality management, warehousing cost reduction, and asset tracking. It’s also a notable resource for predictive maintenance, which can minimize or eliminate unscheduled shutdowns. AI supports smart manufacturing by recognizing trends and quickly solving problems as they emerge.

#3 Predictive Maintenance

Tying-in with AI is the use of predictive maintenance in smart manufacturing. One of the biggest benefits we can expect to see for manufacturing companies over the next few years is improved predictive maintenance. This will help maintain and manage assets more efficiently by using AI systems to predict when a machine or product will need attention before it’s too late.

#4 Industrial IoT aka IIOT

IIOT represents a multi-phased journey that intertwines machines and operations to make work more productive and interconnected. Last year, only 10% of manufacturing companies used IIOT in their operations, but that number is expected to increase to nearly 50% by 2025. The key to enabling this tech trend for smart manufacturing will be implementing its strategies over time for sustained benefits. Although it will continue to grow gradually, manufacturers that don’t start implementing this now risk falling behind quickly as competitors reap its benefits throughout their production process.

#5 Hyperautomation

Hyperautomation is a new concept that was introduced by Gartner in 2019. Its goal is to automate OT (operational technology) and IT (information technology) processes as fast as possible. It supports scalability with the help of multiple technologies, tools, and platforms that allow for rapid growth, including AI and machine learning. Through unified, wholistic, and value-driven workflows, technologies can be synchronized to help manufacturing facilities operate around the clock with remote operations. It’s been reported that roughly 72% of organizations were on the hunt for hyperautomation when the pandemic hit. According to the World Economic Forum, industry leaders could see as much as a 70% gain in productivity with automation.

#6 Moving away from B2B to B2C

B2B buyers are starting to think like B2C consumers. As B2B evolves, the demands traditionally associated with B2C are calling on them to provide more convenient and personalized digital experiences. It's important for manufacturers to look into different channels like eCommerce platforms and website experiences that offer product descriptions, supporting information including manuals, and upsell/cross sell recommendations.

#7 3D Printing a.k.a Additive Manufacturing

The additive manufacturing industry expanded to $12.8 billion just in the past year. It has grown so much throughout recent years that manufacturers have been forced to change how they tackle issues. What was once used as to conceptualize a product through prototyping is now being viewed as an avenue for mass customization and on-demand production. Complex designs can be created with little waste, making it easy to alter designs, reduce costs for high-value parts, and minimize lead time. Parts that once required assembly as multiple pieces can be constructed as a single object, increasing their durability. Additive manufacturing is also being used to fabricate replacement parts that are no longer being produced. The applications for this technology will continue to grow steadily to support the future of smart manufacturing.

#8 Digital Twins

Digital twins are digital replicas of objects in the physical world. In smart manufacturing, they are used to create simulations that predict how a product or process will perform. Whether the focus is on a single component of a process or the improvement of an entire production line, this technology is being applied to prevent costly failures and drive innovation.

#9 Green Manufacturing

With global temperatures rapidly increasing, manufacturing companies are starting to shift to more sustainable materials to help reduce the impact on the environment. Using a circular economy model of production is one way they’re working to get there. These practices reuse, repair, refurbish and recycle existing materials and products for as long as possible to cut down on waste. More manufacturing organizations will join frameworks like the Science Based Targets initiative (SBTi) to legitimize their commitments to sustainability and create more transparency around production practices. Scaling new technology will guide improved efficiency and reduce resource consumption as more manufacturers adopt green practices.

#10 Virtual and Augmented Reality

Virtual reality allows us to experience our senses through a defined lens. It’s used in smart manufacturing to replace the need (and cost) for physical prototyping by offering realistic views of models in real-time. VR also offers a new approach to training and simulations. Augmented reality is digital technology closely related to VR, but instead of being completely immersive, it overlays 3D imagery onto manufacturing equipment to do things like guide repairs or identify problems. These immersive technologies are closely related and are helping the manufacturing industry cut costs, reduce human errors, and maintain better equipment.

Concluding Thoughts

Maximizing the interconnectivity of data is crucial for sustainable and scalable smart manufacturing. CRM solutions specialized for the industry help support these data goals. Learn how TAI can help you find the right CRM for your needs by visiting the manufacturing page on our website.